Why Degreasing Is Key To Effective Ring, Pinion and Gear Care

When it comes to heavy industries, like mineral mining and oilsands mining, the heavy-duty machinery used has to operate under heavy load. This places the systems driving the machinery under extreme pressure, so it’s little wonder proper gear maintenance is an acute priority. But while many identify lubrication as critical, using an effective gear degreaser has a greater impact on ring, pinion and gear care.

When it comes to heavy industries, like mineral mining and oilsands mining, the heavy-duty machinery used has to operate under heavy load. This places the systems driving the machinery under extreme pressure, so it’s little wonder proper gear maintenance is an acute priority. But while many identify lubrication as critical, using an effective gear degreaser has a greater impact on ring, pinion and gear care.

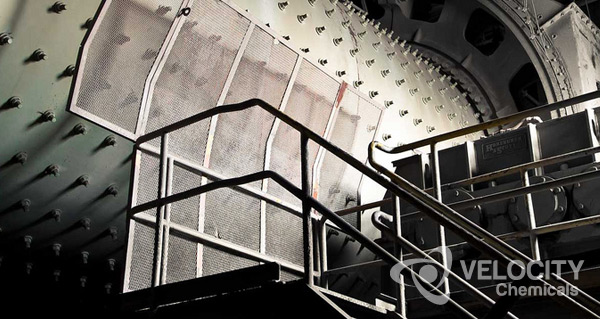

Open gear drives (which are also known as girth gears) are recognized as the best type to work under such conditions. This is partly because they are designed specifically to drive some of the largest machinery around, including grinding mills, tubular drums and rotary kilns. But it’s also because they are considered the most economical for machinery operating under heavy load.

What is more, they are known to enjoy long lives when properly maintained. So making the effort to get a ring, pinion and gear care plan right is clearly a wise investment.

Important Role Of Gear Degreasers

For most of us, lubricants play an obvious role in maintaining machinery, coating components to provide full protection. But their effectiveness in gear maintenance depends greatly on traits like adhesiveness and viscosity.Any lubricant needs to be highly adhesive to ensure it clings to the gears and tooth flanks and not simply drip off. Meanwhile, as a measure of flow resistance, viscosity is important because rising temperatures during operation can thin the lubricant, adversely affecting its adhesive quality. Higher viscosity helps counter this reaction.

But in all cases, the effectiveness of a lubricant depends on it having a clean surface to cling to – which is why the role of the degreaser and cleaner is so important in ring, pinion and gear care. Research shows that having a smooth, clean metallic surface is essential in getting the best performance from lubricants and most impressive gear maintenance results.

3 Key Traits For Best Ring, Pinion And Gear Care

1. Minimizes Downtime – The issue of downtime is a concern for any industrial operation, with time spent carrying out gear maintenance sometimes affecting productivity. So, finding a gear degreaser that can break down and remove grease and other soils during operation is essential.

2. Contains Extreme Pressure Additives – This is the ingredient that allows a degreaser to do its work, while also lubricating and cleaning gears, during operation, even under heavy load. Extreme loads can make it difficult for chemical products to work effectively, but EP Additives strengthen these products to ensure higher performance and better results.

3. Breaks Down Stubborn Grease – Some grease can build up in very hard-to-reach places, making it very difficult to break down and remove. This is especially true for lubricants that contain lithium, asphlatines and molybdenum disulfide, which can build up in the root of the gear teeth over time. The gear degreaser, therefore, has to be tough enough to handle these deposits if the ring, pinion and gear care is to be as effective as it should be.

Degreasers From Velocity Chemicals

As one of leading manufacturers and distributors of degreasers and cleaners for heavy equipment, Velocity Chemicals has long been a trusted partner of some of North America’s biggest mineral mining and oilsands mining companies. Two of the products in our range have been specially formulated for the heavy industry sector and provide excellent ring, pinion and gear care. These products are:GEARZ-EP – is a natural lubricant fortified with extreme pressure additives for lubricating, degreasing and cleaning of mill gears while operating under load. Fast and efficient, it’s breaks down and lifts out some of the most stubborn greases while also providing protection to rim, pinion and gear systems. Biodegradable, GEARZ-EP contains no chlorohydrocarbons and adheres to the highest health and safety standards making it a greener and safer high-performance cleaning solution. GEARZ-EP is typically heated to 50-60°C prior to use.

GEARZ-EP-LT – is a solvent-based cleaner that has been specially formulated for ambient temperatures, and can deliver high-quality cleaning and degreasing results even under heavy load. Fast working and easy to apply, it is tough on difficult-to-remove greases but protects gears by reducing the risk of galling. It’s also biodegradable, contains no chlorohydrocarbons and adheres to the highest health and safety standards making it a greener and safer high-performance cleaning solution.

Photos courtesy of freeside510 ![]()